|

Warehouse, space for 2’500 palettes Approx. 800 different raw

materials, Temperature and humidity are

monitored, ERP-system controlled, full traceability

|

|

Gelatin preparation, intermediate storage tanks, addition of

colorants and flavors possible, all manufacturing steps are

monitored and controlled by ERP-System, full traceability

Raw granular gelatin is mixed with glycerine and water. Coloring

agent can also be added at this stage. Glycerine acts as a

plasticizer in the gelatine compound. Other plasticizers can also be

used either alone or in combination with glycerine, such as

sorbitol. The proportions of each ingredient involved in the mixture

should be considered carefully because the shell material needs to

be adapted to formulation and/or environmental requirements. For

instance the gelatin recipe may need to be adjusted to account for

acidity, water content of the fill material or high humidity

environmental conditions.

|

|

Fill mass preparation, steel tanks, intermediate storage tanks,

GMP environment.

A homogeneous fill material plays a vital role to ensure the

uniformity of each Softgel dose. Various equipment should be

available, such as processing tanks, high-shear mixer, homogenizer

and variety of mills is use.

|

|

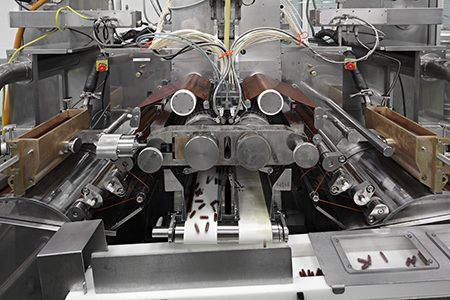

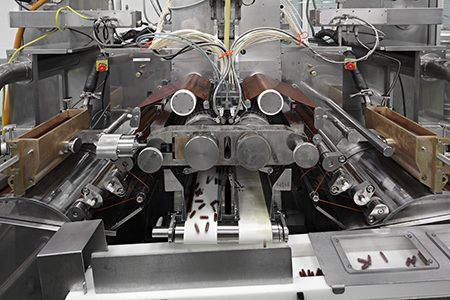

Encapsulation machine, encapsulation part (“heart” of encapsulatin

machine) Temperature and humidity are

monitored, ERP-system controlled, full traceability.

Encapsulation is the manufacturing process that brings the gelatin

shell and the fill material together to form Softgel capsules. It

takes place in a closed environment where the relative humidity is

around 20%. The gelatin shell and fill material are brought together

simultaneously in the encapsulation machine.

|

|

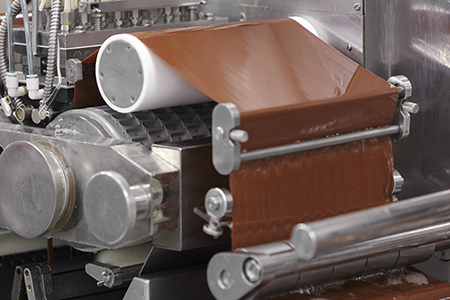

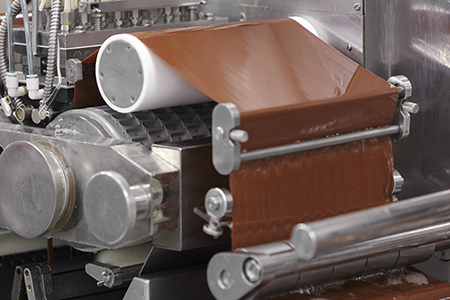

Encapsulation machine, gelatin ribbon. Temperature and humidity

are monitored, ERP-system controlled, full traceability.

A pump delivers the warm gelatin over two chilled drums which are

located at both opposite sides of the machine, through a spreader

box that sits over each drum. The warm liquid gelatin flows over the

drums and this transforms the liquid gelatin into two solid ribbons

of gel. The left and right ribbons pass over rollers which feed them

through two die rolls. These die rolls determine the shape and size

of softgels and cut the Softgel shell from the ribbons as they turn

around.

|

|

Encapsulation machine, converter ribbon from encapsulation machine to

drying tumbler.

Temperature and humidity are monitored, ERP-system controlled,

full traceability.

Performed by a tumble dryer. Tumbler drying the softgels to removes

approximately 30 percent of the water content in the softgel

capsules.

|

|

Drying room, drying tumbler

Temperature and humidity are monitored, ERP-system controlled,

full traceability.

Softgel capsules are transferred to the drying room where high air

flow exists and they stay around 24 to 48 hours or until the

softgels become hard enough

|

|

Calibration and sorting

Temperature and humidity are monitored, ERP-system controlled,

full traceability

Fully automatic softgel sorting machine equipped with electronic

sensors is used to sort and remove the damaged, misshaped, broken

etc. gelatin capsules,

Afterwards manual visual inspection takes place. Any misshaped,

damaged and/or not fully filled capsules are removed manually by

using an inspection table.

|