The Aloha Medicinals Advantage

Full Spectrum Mycoproducts™

There is a lot of confusion today from all the marketing claims on the internet about what form of mushroom product is the best to use. Some say it is the fruitbody, or the mycelium, or a hot water extract standardized for some particular compound. There is a lot of complex bio-chemistry going on in the mushroom kingdom that can be valuable for its health giving potential. We have addressed these issues here so you can decide which health supplement raw materials are the best for your use.

Let’s start with some Definitions

Fruitbody

‘Fruitbodies’ are the mushrooms you see growing out of the ground or off of trees or organic debris. They are the reproductive part of the fungal organism, like the flower of a plant. Just like flowers will only bloom during a certain season, fruitbodies will only form in response to some stress in the environment, such as heat or cold, fire or flood, running out of food, or some other stress that forces the organism into a “reproduce or die” stage. The mushroom fruitbodies that you see are strictly the reproductive portion of the fungus at the end of its life cycle.

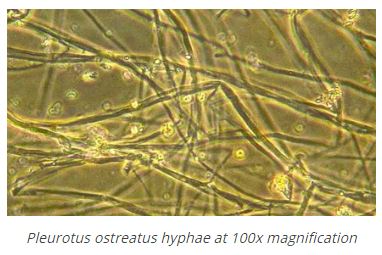

Mycelium

‘Mycelium’ is the growth form of the fungal organism. This is the state in which all of the life processes other than reproduction occur, such as growth, feeding, and competing for survival (including antibiotic, antifungal and antiviral compound production). In cultivated mushroom products, the mycelium can be grown on a solid substrate of some organic material that it would naturally grow on. For production of most mushroom-derived drugs, the compounds are extracted not from the mycelium, but from the broth or substrate the mycelium is grown in.

Extracts

‘Extract’ is a word that covers a lot of possibilities. Extracts are usually made from either mushrooms or mycelium, which are extracted with some type of solvent with the intention of concentrating some desirable portion and eliminating or reducing some non-desirable portion of the fungus. There are a number of solvents which are used, depending on which type of compounds the extractor is hoping to concentrate. The two most common solvents used are Alcohol and Water. Extracts tend to be more expensive than raw materials and they may be either more potent or less potent than the raw material, depending upon which compounds are being concentrated and the desired end use of the material. The following section should clarify how extracts are made, what their uses are, and why there is so much misunderstanding about them.

Full Spectrum

‘Full Spectrum Myco-Products’ are the complete fungal material consisting of all the biologically active components, including the mycelium, primordia, fruitbodies, and most importantly, the extra-cellular compounds produced throughout the entire life cycle of the organism. It is these extra-cellular compounds (compounds that are excreted outside of the cell and into the surrounding environment) that are responsible for the main medicinal properties known from the fungal kingdom, such as all the antibiotic properties, antiviral properties, antifungal properties and all the other ‘survival’ compounds that the fungus produces to give itself an advantage over the competing bacteria and microbes in the highly competitive environment in which it lives. These secondary metabolites have opened up the frontiers of medicine, with such breakthroughs as antibiotics and cholesterol lowering drugs.

Basis for Quality Determination in Medicinal Mushrooms

History

While medicinally active mushrooms have certainly been collected from nature and used for a long time, the cultivation of mushrooms specifically for the production of medicinal compounds is a new practice, dating only from the late 1970’s. Since that time there have been a number of bio-active ‘compounds of interest’ identified from mushrooms, including compounds from the fruitbodies, from the mycelium and from the residual culture broth or solid substrate residue.

The Process in Detail

Mushrooms belong to the Kingdom of Fungi. It has been known for a long time that fungi produce potent bioactive compounds with medicinal properties. Classic examples of this fungal-derived class of medicines are antibiotics, such as Penicillin.

Other examples of the production of fungal bioactive compounds are the beer and wine industries. In those cases the substrate is fruit juice, malt extract, or some other source of sugars, vitamins and minerals, and the fungus species used is a brewer’s yeast called Saccromyces cerevisiae. As the fungus grows (just like mushrooms, all yeasts are fungi) it secretes into its immediate environment (the tank full of juice or malt, called the ‘substrate’) all of the bioactive ‘compounds of interest’, which are the alcohols, the colors and flavorings. These are all found in the substrate and not in the yeast. Similarly with mushrooms, the mushroom fruitbodies typically have the lowest concentration of bioactive compounds present, while the mycelium is the growing portion and thus contains a much higher proportion of extra-cellular bioactive metabolites.

In developing our production processes, Aloha Medicinals looked at the chemistry of the wild collected fruitbodies, of the mycelia and of the extra-cellular compounds, and all that was known about the bioactivity of each in the human body. We then developed special growing methods including custom made growing chambers, strictly defined growth substrates (no sawdust, straw or compost is used) and specially modified growth parameters such as climate control for temperature, light cycle, air quality and composition to maximize the production of targeted medicinal compounds. By controlling each aspect of the growth cycle, Aloha Medicinals is able to produce the highest quality and the most consistent medicinal mushroom products available anywhere today, while ensuring against all possible contamination of pesticides, herbicides or other residues.

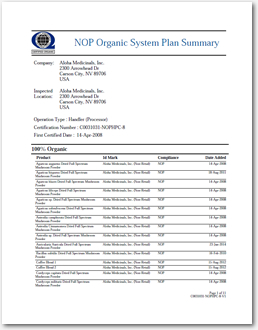

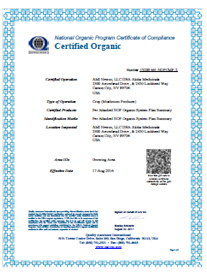

If you want the highest quality medicinal mushroom products available today, Aloha Medicinals is your best choice. 100% Certified Organic by the USDA and EU. Whether you need Full Spectrum Myco-products, or a concentrated extract

About Us

Aloha Medicinals products are setting the Gold Standard in the health supplement field; we pride ourselves in offering 100% American Made products.

The Beginning

Aloha Medicinals started out on the island of Maui by a group of scientists and health care experts interested in growing Reishi, Cordyceps, and other medicinally important mushroom species. With our first lab built in Haiku, Maui, in the spring of 1999, Aloha Medicinals was focused on producing medicinal mushrooms of the highest quality right from the beginning, and this approach quickly paid off with customer demand. In the spring of 2002 the company moved to Santa Cruz, California, where we took over the Sunrise Spawn Company, which had originally been the Stoller Research Laboratory.

Dr. Benjamin Stoller, who started Stoller Research in Santa Cruz back in 1955, was one of the pioneers in the field of Mushroom cultivation, especially the cultivation of button mushrooms. When Aloha Medicinals took over the Sunrise Spawn/Stoller Research facility, besides gaining a fully qualified staff and manufacturing equipment, we also inherited all of Dr. Stoller’s original research material on mushrooms. Doc Stoller, as he was known throughout the industry, died in 1989, and though much of his research had already been published, we obtained all of Doc Stoller’s lab notebooks on projects he had worked on for over 60 years. Some were dead ends, some were projects that had started and petered out for one reason or another, and some of these were projects that lead to patented breakthroughs in the field of Mushroom Cultivation. This wealth of information was one of the reasons Aloha Medicinals catapulted to the top of the medicinal mushroom industry in just a few short years. By the summer 2007, demand increased for our products to the point where we had to look outside the Santa Cruz facility for our product manufacturing. In June 2007 Aloha Medicinals moved our entire operation to Carson City, Nevada, right at the base of the Sierra Nevada Mountains, at an elevation of 5,000 ft. This is the ideal location for maintaining climate control growing conditions, including the reduced air pressure necessary for producing the world’s most potent medicinal mushroom species.

What’s Happening Today

Today, after seventeen years in the cultivation business, Aloha Medicinals is the industry’s leading company in the cultivation of medicinal mushroom species. We have more than 1,000 unique species in our culture bank, making it the largest privately owned culture collection of medicinal mushroom species in the world. At any given time we have 100 different species in cultivation. Aloha Medicinals has a monthly capacity of over 40 tons of finished raw material, which we currently supply as ingredients to over 700 companies for use in their formulas. We currently export raw materials and finished products to over 60 countries, which led to Aloha Medicinals being recognized with the “Exporter of the Year Award” by the U.S. Department of Commerce in 2008, the second year in a row that Aloha received national recognition for our medicinal mushroom raw material exports.

Our staff includes Mycologists, Microbiologists and Health Care Professionals from several fields of study. We are the manufacturers of the raw materials for the products we offer, and all of our raw materials and dietary supplement ingredients supplied to the industry are fully USDA and EU Certified Organic. We provide raw materials for the supplement and pharmaceutical industries, as well as to the public, with the high-quality all American Made dietary supplement options they need. We use only third party certified, non-irradiated, non-GMO, natural ingredients in our manufacture of the finest health supplements available today. These are All Natural, All Organic, All Third Party Certified products, which are produced in a state-of-the-art FDA certified Good Manufacturing Practice (cGMP) facility.

Aloha Medicinals products are setting the gold standard in the health supplement field, and we pride ourselves in offering all 100% American Made products – products that undergo the most rigorous analytical testing by the top FDA registered labs in the country. All of our raw materials are also verified by DNA sequencing through the U.S. National Institute of Health, National Center for Biotechnology Information (NCBI) Genebank. This ensures that you are not only getting exactly what you pay for, but if you are a manufacturer using our products in your formulations, Aloha Medicinals will also make your GMP process flow much more smoothly through our material certification program and offer extensive technical support for the raw materials used in your products.

Worldsalud Limited

2003, 20/F, Remington Centre, 23 Hung To Road, Kwun Tong, Hong

Kong

Telephone: +852-27933108

Fax: +852-27933107

Email: [email protected]

Quality Guaranteed

Aloha Medicinals Inc. is world’s largest and most technologically advanced producer of USDA and EU Certified Organic medicinal mushrooms.

Aloha Medicinals Inc. is one of the largest and most technologically advanced producers of USDA and EU Certified Organic medicinal mushrooms and mushroom-derived compounds in the world today. All of the Aloha Medicinals’ raw materials are produced in the United States in Carson City, Nevada under FDA certified Good Manufacturing Practice (cGMP) regulations, licensed by the State of Nevada as a food manufacturing plant, fully certified 100% Organic under USDA and EU regulations. All Aloha Medicinals mushroom products are grown using only Certified Organic, American produced raw materials, with no GMO or imported ingredients used.

Aloha Medicinals Inc proprietary solid-state fermentation process

Aloha Medicinals currently produces more than 100 different

species of mushrooms,

using a proprietary solid-state fermentation process unlike any

other. This

proprietary process ensures the maximum content of active

compounds in the finished

products, guarantees absolute consistency from lot to lot, and

ensures that no heavy

metals, pesticides, herbicides or other contaminants are present

in the finished

products. These raw materials are available at bulk pricing for

use in custom

formulations, or we can provide extraction, concentration,

purification, blending

and even full private-label services to help develop your next

product.

We can provide the raw materials you need for your products,

whether they are whole

mushroom materials, or concentrated and purified extracts, right

down to purified,

single-molecule research grade compounds.

Aloha Medicinals Sterility Verification

Every lot of material is thoroughly analyzed through independent

FDA certified

laboratories, ensuring quality and compliance with strictest

standards worldwide.

Every lot of material we produce is 100% guaranteed to exceed

the standards set for

all microbial and quality analysis testing.

If you have special requirements we can test for any compound

you may need.

Aloha Medicinals Genetic Verification

All our mushroom strains are genetically verified through DNA sequencing by the United States government’s National Institute of Health-National center for Biotechnology Information {NCBI}. A copy of this independent DNA verification is included with every order at no cost to you, simplifying your GMP validation process. No other manufacturer of Medicinal Mushroom products offers this third-party genetic validation.

Aloha Medicinals Organic Verification

All products produced by Aloha Medicinals are 100% USDA and EU Certified Organic by Quality Assurance International –the worlds largest and most prestigious organic certifier!

Aloha Medicinals Purity Verification

Every production lot is independently analyzed for comprehensive panel of nearly 100 different heavy metals. Aloha Medicinals GUARANTEES complete freedom from all contamination from heavy metals, pesticides, herbicide and all other contaminants.

Aloha Medicinals Nano Technology–Micronization service

Aloha Medicinals is the only manufacturer of Medicinal Mushroom

Nano products.

We also offer micronization service down to less than one micron

in particle size to

ensure maximum bio-availability, particularly for the high

molecular weight

compounds.

“Nanoparticles, sometimes called sub-micronized particles, those

of 1 microns or

less in size, demonstrate remarkable ability to increase the

body’s ability to

absorb nutrients and medicines,” said John Holliday, president

and chief scientific

officer of Aloha Medicinals.

“The smaller the particle size, the more efficient the nutrient

or drug becomes.

That means that ultimately less of the drug is required to

obtain a therapeutic

affect, which in turn means that medicines not only cost less,

but absorption is

quicker and the potential for side-effects is minimized.”

Roger Scott, the Aloha’s CEO said that the new technology opens

opportunities in the

areas of dietary supplements, OTC and prescription drugs,

cosmetics and liquids.

Aloha Medicinals Library of Mushroom Cultures

Aloha Medicinals has the largest privately owned medicinal mushroom culture bank in the world with over 5000 different cultures. We can produce any species of mushroom you may require.

Aloha Medicinals is world’s largest producer of super potent Cordyceps.

Aloha Medicinals Cordyceps is the only Bio-Identical Cordyceps

grown in patented low

oxygen, low temperature conditions, just like nature! And Aloha

Medicinals is the

only Cordyceps that is “Certified Genetically Authentic” through

independent

third-party DNA testing and Verified through the National

Institute of Health gene

bank.

Dr. John Holliday and his company – Aloha Medicinals have spent

years researching

the best way to grow Cordyceps Sinensis in a safe, cultivated

environment – while

maintaining all the health benefits that wild Cordyceps Sinensis

affords. Dr.

Holliday experimented with different temperatures, different

oxygen levels, varied

growing conditions and different substrates – all while

performing DNA testing to

make sure the Cordyceps Sinensis he cultivated would meet the

potency of wild

Cordyceps.

Aloha Medicinals made a Cultivated Cordyceps that was 3 Times MORE potent than Wild Cordyceps!

Aloha Medicinals hard work paid off with a Cultivated Cordyceps Sinensis that is…

- Guaranteed to be the most potent Cordyceps in the world – 3 times more potent than Wild Cordyceps

- The only Cordyceps Sinensis that is grown in low oxygen, low temperature conditions – just like nature!

- Guaranteed 100% DNA Certified through Independent testing to be authentic Cordyceps Sinensis

- Guaranteed 100% USDA Certified Organic

- Guaranteed 100% Vegetarian – Absolutely no insect residue

- Guaranteed to be derived directly from Tibetan Strains

- Guaranteed to be 100% American Grown in FDA registered biotech facility

A review on how Aloha Medicinals was able to organically cultivate the most potent Cordyceps in the world that is not only bio-identical genetically, but also bio-identical in it’s analytical signature.

Cordyceps has been used for a long time in China and Tibet. For

at least a thousand

years according to the written record. It was not until 1972

that the first

successful Cordyceps cultivation was achieved. The first

Cordyceps cultures were

isolated by the Chinese Academy of Sciences in that year. These

strains were not

isolated from Tibet, where most of the top quality Cordyceps

comes from, but rather

they were isolated from specimens found in Qinghai province in

Central China.

Originally three different strains of Cordyceps were isolated.

The first three

strains, named CS-1, CS-2 and CS-3, did not have the fast growth

characteristics

that make commercial cultivation practical. It was the fourth

culture that had been

isolated by this institute, named CS-4, that was hardy and fast

growing. So this

CS-4 strain was chosen for commercial production.

This CS-4 culture proved itself a good candidate for commercial

growth, so it was

evaluated as a substitute for wild Cordyceps. It was tested for

its medical

potential, and by 1988 it had been approved in China as a

medicine under the name

Jin Shui Bao. As part of the approval process to bring this to

market, many clinical

and safety trials were conducted showing its efficacy and

safety. That is the reason

there are so many scientific articles available on this

particular strain called

CS-4.

But that happened a long time ago in terms of science. Think of the advances that have been made in all the sciences over the last 44 years. That is how long ago CS-4 was isolated. CS-4 is a good dietary supplement, but just because CS-4 was the first Cordyceps cultivated and studied certainly does not mean it is still the best choice today, yet many people today are taken in by the marketers that still use that early information on CS-4, telling their customers that CS-4 is the best Cordyceps for their use. This is just simply incorrect. Back in 1972 when CS-4 was isolated there was no such thing as DNA analysis. So at that time it was not realized that CS-4 contained only a part of the Cordyceps genome. CS-4 is closely related to Cordyceps sinensis, but it is not “true Cordyceps sinensis”. CS-4 is a related species called an Anamorph.

Let’s jump ahead nearly 40 years and look at where Cordyceps cultivation is today: Aloha Medicinals set out to cultivate the most potent Cordyceps back in 1999. Aloha started with the purchase of CS-4 cultures from private manufacturers in China. This was the first strain of Cordyceps Aloha produced when the company was formed on Maui in 2000. In 2001 Aloha purchased another ten Cordyceps strains from the Government of China. But Alohas research using DNA analysis and the most up-to-date analytical methods such as GC/MS and HPLC/MS showed that none of these “Cordyceps” strains were identical to wild Cordyceps. They were all related anamorphs, but they were not “True Cordyceps”.

Aloha tried every possible combination of culture techniques and growth medium, but realized that by using these part-spore cultures there was no way to gain the full potential which is known to occur in wild Cordyceps. To achieve the wild Cordyceps quality requires a much more complex approach, involving the replication of the wild Cordyceps growth conditions and triggering fusion between several part-spore cultures to achieve the full Cordyceps DNA sequence. This approach was so unique it was issued the only patent ever granted for the hybridization of mushrooms! This is the only cultivated Cordyceps available today that is genetically and analytically Bio-Identical to the wild Cordyceps occurring in Nature. This is not to be confused with Genetic Modification. Aloha Medicinals absolutely guarantees there are NO genetically modified organisms (GMO) in any Aloha Medicinals product. Aloha is opposed to the GMO approach, as well as this being forbidden under USDA and EU Certified Organic standards. Quality has no substitute. Aloha Medicinals makes the VERY BEST medicinal mushroom products in the world today

Even after Aloha had developed these bio-identical cultures though, which were 100% Cordyceps sinensis in every way, there was still a problem: The Cordyceps being grown in cultivation was still not as potent as the wild collected Cordyceps. To try and resolve this problem, Aloha Medicinals scientists undertook an expedition into the heartland of wild Cordyceps habitat, central Tibet. In May and June of 2006 Aloha Medicinals conducted one of the most comprehensive scientific research expeditions ever undertaken in the mountains of Tibet to study the natural growth parameters of wild Cordyceps. Working with the local nomad people, Aloha identified several hundred Cordyceps specimens growing directly from the ground. Aloha carefully measured all the growth conditions there, such as pH, soil and air temperature and composition, moisture content in the air and soil, the other micro-organisms found in the area, air pressure and virtually everything else that could be measured, Aloha did.

Aloha brought this information back to the lab, and developed entirely new methods of cultivation, which have resulted in Cordyceps that is not only bio-identical genetically, but also bio-identical in it’s analytical signature. Bringing the latest of 21st century American biotechnology to this field has resulted in a quantum leap in Cordyceps cultivation, reducing the cost and increasing the quality of cultivated Cordyceps. These cultivation methods involved building special growing chambers where the oxygen is held at 50% of the normal atmospheric oxygen, and the temperature is held at just above freezing. This exactly replicates the conditions found during the growing season in Nepal and Tibet at 18,000 feet (5400 meters) elevation. This Low Temperature, Low Oxygen growth is also patented. Aloha Medicinals is the only company in the world that grows Cordyceps using these techniques.

How can you prove Aloha Medicinals Cordyceps is more potent than Wild Cordyceps?

Excellent question. One of the most accurate tests to identify a specific herb or botanical is High Performance Liquid Chromatography with Mass Spectrometry (HPLC/MS). Don’t worry, the name makes it sound more confusing than it really is. Basically, with HPLC you measure the active ingredients (or analogs) that make up your sample.

With Cordyceps Sinensis the analogs are HEAA (Hydroxyethyl Adenosine Analogs). An HPLC test is a very accurate way to measure the HEAA in different Cordyceps samples. The higher the HEAA – the stronger the Cordyceps. Here is the HPLC test for Aloha Medicinals Cordyceps Sinensis versus Wild Cordyceps Sinensis…

![]()

As you can clearly see, the Blue Line (Aloha Medicinals Cordyceps) peaks higher than the Red Line (Wild Cordyceps) for every single component.

In effect, Aloha Medicinals has taken the incredible Wild Cordyceps mushroom and made it 3 times stronger!

Aloha Medicinals’ Quality Control and third-party DNA certification

Aloha Medicinals’ Quality Control is the best in the industry. All mushroom species grown are third-party DNA certified through the U.S. National Institute of Health – National Center for Biotechnology Genebank (NCBI), and all required chemical and microbial assays are performed by independent FDA certified, third-party analytical laboratories. A Certificate of Analysis and a full chemical and DNA profile is provided with each lot. While most manufacturers test only for the few items required by FDA such as the total plate count and e-coli content, at Aloha Medicinals we analyze for a comprehensive array of substances. This includes more than 90 heavy metals, full polysaccharide profile including beta glucans, heteropolysaccharides and residual starches, all microbial and sterility tests, plus any specialized analysis that may be required by the client.

NEW:

Aloha Medicinals started to use the World’s First

and Only Certified

Organic Vegetable Capsulesfor its finished products.

The rule on marketing a product that is labeled as “USDA Certified Organic” is that the product needs to be 100% Organic. Even 99.9% is not good enough, it must be 100%. All Aloha raw materials are 100% Certified USDA and EU Organic. If they are sold as powders, or if they are put into other foods or tablets that are also 100% Certified Organic, they can and should be marked as USDA Certified Organic. However, if Aloha organic powder is put into a capsule shell that is not Certified Organic, the total product is no longer 100% certified Organic. In more details: if 500 mg is put into the capsule, the total weight is 590 mg, but only 500 mg is Certified Organic. The remainder is not organic. In other words, there is only 85% organic material, and 15% non-organic material in the total capsule weight, so the product cannot be marked USDA Certified Organic.

This has been the past.

The good news is Aloha between the first companies in the world started to

use World’s First and Only Certified Organic

Vegetable Capsules. For

the first time now you will be able to claim on your label

that your total product is Certified

Organic (raw

material USDA and EU 100% certified organic as well as the new capsule that

is 100% USDA

Organic).

Law explained: Questions and Answers: Click the link:

According to U.S. – European Union

Organic Equivalence

Arrangement

Aloha Medicinals – “Exporter of the Year Award” honored by the U.S. Department of Commerce

Due to this state-of-the-art manufacturing and unexcelled quality control program, Aloha was proud to accept the U.S. Department of Commerce “Exporter of the Year Award” for its top quality exports in the field of pharmaceutical and supplement raw materials. Aloha currently supplies over 700 companies in more than 60 countries with raw materials for their branded products.

Aloha Medicinals guarantee there are no other Medicinal Mushroom products available anywhere in the world today with more potency or consistency or a higher quality than the raw materials produced by Aloha Medicinals Inc.

Creating Private Label Products for You.

Aloha’s staff includes Mycologists, Microbiologists, Biochemists, Veterinary and Human Health Care Professionals from several fields. You can choose one of our proven formulas or, if you have your own formula in mind, we can manufacture it for you. We are pleased to work with you in developing your next product. We will manufacture any product to your specification! Please send us email with your questions to [email protected] or to [email protected]

Here is a list of some of our more popular strains available for custom formulation:

| Coriolus versicolor | Hypsizygus ulmarius | |

| Cordyceps sinensis – many strains Caterpillar Fungus |

Hypsizygus marmorius | |

| Cordyceps militaris | Inonotus obliquus Chaga | |

| Agaricus blazei ABM or Royal Sun Agaricus | Lentinula edodes Shiitake | |

| Agaricus subrufescens | Phellinus linteus | |

| Flammulina velutipes Enokitake | Piptoporus betulinus | |

| Fomes fomentarius | Pleurotus ostreatus Oyster Mushroom | |

| Ganoderma applanatum | Pleurotus pulminarius | |

| Ganoderma lucidium Reishi | Pleurotus tuber-regium | |

| Ganoderma tsugai Red Reishi | Polyporus umbellatus | |

| Grifola frondosa Maitake | Poria cocos Fu Ling | |

| Hericium erinacea Lions Mane | Trametes versicolor Turkey Tails |

|

Aloha

Medicinals Agaricus

Blazei available as Full Spectrum MycoProduct™ and as Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

|

|

Aloha

Medicinals Full

Spectrum Chaga MycoProduct™ blended 50/50 with sustainably harvested wild collected Chaga

|

|

|

Aloha

Medicinals GanoUltra™

Full Spectrum MycoProduct™ USDA and EU Certified

Organic

|

|

|

Aloha

Medicinals GanoSuper™

Concentrated 4:1 purified and micronized extract

Special Low Taste/Low

Odor extract ideal for drink application or high

potency supplements

USDA and EU Certified Organic

|

|

|

Aloha

Medicinals Red Reishi™

available as Full Spectrum MycoProduct and as Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

|

|

Aloha

Medicinals Grifola

Frondosa Available as Full Spectrum MycoProduct™ and Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

|

|

Aloha

Hericium Erinaceus

available as Full Spectrum MycoProduct™ and Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

|

|

Aloha

Medicinals Lentinula

edodes Available as Full Spectrum MycoProduct™ and Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

|

|

Aloha

Medicinals Cordyceps is

the only Bio-Identical Cordyceps grown in patented

low oxygen, low

temperature conditions, just like

nature!

|

|

|

Aloha Medicinals Polyporus umbellatus

Full Spectrum

MycoProduct™ USDA and EU Certified Organic

|

|

|

Corioulus Versicolor Available as Full

Spectrum

MycoProduct™ and Concentrated 8:1 and 16:1 purified & standardized extract USDA and EU Certified Organic

|

The Aloha Medicinals Advantage

Full Spectrum Mycoproducts™

There is a lot of confusion today from all the marketing claims on the internet about what form of mushroom product is the best to use. Some say it is the fruitbody, or the mycelium, or a hot water extract standardized for some particular compound. This is an important question and the answer should be based in scientific fact, not on historical usage or on someone’s opinion. There is a lot of amazingly complex bio-chemistry going on in the mushroom kingdom which can be valuable for its health giving potential. We have accurately addressed this issue here so you can decide which health supplement raw materials are the best for your use or for use in your product formulation.

Let’s start with some Definitions

Fruitbody

‘Fruitbodies’ are the mushrooms you see growing out of the ground or from that old dead tree. They are the reproductive part of the organism, like the flower of a plant. Just like flowers will only bloom during a certain season, Fruitbodies will only form in response to some stress in the environment, such as heat, or cold, fire or flood, running out of food, or some other stress that forces the organism into a “reproduce or die” mode. The mushroom fruitbodies that you see are NOT the growth form of the mushroom organism. It is strictly the reproductive part of the fungus at the end of its life cycle.

Mycelium

‘Mycelium’ is the growth form of the organism. This is the state in which all of the life processes occur, such as growth, feeding and competing for survival (including antibiotic, antifungal and antiviral compound production). In cultivated mushroom products, the mycelium can be grown by fermentation in a tank full of liquid as beer and wine are “grown”. This is a highly unnatural growth condition, and mushrooms grown this way do not have the same chemical profiles as those that are grown naturally. Another way that medicinal mushroom mycelium can be grown is on a solid substrate of some material that it would normally grow on – which is the natural growth condition. For production of most mushroom-derived drugs, the compounds are extracted not from the mycelium, but are actually extracted from the broth or substrate the mycelium is grown in.

Extracts

‘Extract’ is a word that covers a lot of possibilities. Extracts are usually made from either mushrooms or mycelium, which are extracted with some type of solvent with the intention of concentrating some desirable portion and eliminating or reducing some non-desirable portion of the fungus. There are a number of solvents which are used, depending on which type of compounds the extractor is hoping to concentrate. The two most common solvents used are Alcohol and Water. Extracts tend to be more expensive than raw materials and they may be either more potent or less potent than the raw material, depending upon which compounds are being concentrated and the desired end use of the material. The widely held belief that extracts are somehow “more potent” than other forms of mushroom material is too simplified to be true, and is simply incorrect. But this thinking is the result of historical usage and dubious internet marketing claims, as you will read below. The following section should make it clear so you will understand how extracts are made, what their uses are, and why there is so much misunderstanding about them.

Full Spectrum

‘Full Spectrum Myco-Products’ are the complete fungal material consisting of all the biologically active components, such as the mycelium, the fruitbodies, the spores and by far the most important of all, the extra-cellular compounds that are produced throughout the entire life cycle of the organism. It is these extra-cellular compounds (compounds that are excreted outside of the cell and into the surrounding environment) that are responsible for the main medicinal properties known from the fungal kingdom, such as all the antibiotic properties, antiviral properties, antifungal properties and all the other ‘survival’ compounds that the fungus produces to give itself an advantage over the competing bacteria and microbes in the highly competitive environment in which it lives. These secondary metabolites have opened up the frontiers of medicine, with such breakthroughs as antibiotics and cholesterol lowering drugs. And it is these properties that are removed through most extraction processes. It is only in the 21st century that science has developed practical ways to reliably produce full spectrum myco-products which are now considered the current “Gold Standard” for most mushroom based dietary supplements.

Basis for Quality Determination in Medicinal Mushrooms

History

While medicinally active mushrooms have certainly been collected from nature and used for a long time, the cultivation of mushrooms specifically for the production of medicinal compounds is a new science, dating only from the late 1970’s. Since that time there have been a number of bio-active ‘compounds of interest’ identified from mushrooms including different compounds from the fruitbodies, from the mycelium and from the residual culture broth or solid substrate residue. In almost every case, the main cellular components found in the different life stages are identical. But there are differences in the ‘secondary metabolites’ produced, where substantially greater amounts of particular compounds can be extracted from one growth stage as compared to some other growth stage. Many examples of this can be seen in the scientific article authored by Dr. Solomon Wasser: Medicinal Properties of substances occurring in Higher Basidiomycetes Mushrooms: Current Perspectives (Review) [pdf] published in – International Journal of Medicinal Mushrooms.

What is the most practical way to produce medicinal mushroom products with the greatest effectiveness, while keeping them affordable enough for the general public?

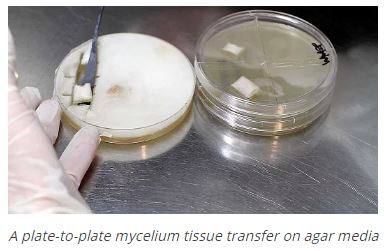

Even just ten years ago this was a problem because solid state fermentation had not yet been perfected, and growing mushrooms in liquid culture as with beer or wine requires extraction of the compounds left behind in the broth in order to capture all the health properties. This processing step raises the cost beyond what is practical for most people to spend on their dietary supplements. It is easy for a company to purchase wild collected mushrooms, or to grow mushroom fruitbodies on a farm and then extract them for supplement uses. To produce medicinal mushroom products with low potency is counterproductive, since they will not have a large consumer following if they do not work. So most companies take the easy approach of growing or buying mushroom fruitbodies, and then making a tea which is spray dried and called a “hot water extract”. Many claim this is the best form to use, or even that it is the only bioactive way to use mushrooms, which is of course nonsense, since mushrooms have been eaten for their health properties for thousands of years. The concept that extracts are better than anything else is yesterday’s science and it does not reflect today’s state-of-the-art knowledge. These “hot water extracts” are certainly better than trying to digest hard woody fruitbodies such as Reishi, but this extraction process entirely misses the potential health benefits which are offered by the extra-cellular compounds, which are not present in the fruitbodies.Some other companies will just grow the mycelium. This can be a better choice than fruitbodies if grown in solid substrate, but the mycelial products can be a problem if they are not produced according to strict FDA certified Good Manufacturing Practice (cGMP) biotechnology sterile tissue culture standards, and some mycelium products often contain up to 70% of unconverted substrate, like rice or wheat. All Aloha Medicinals products are guaranteed to contain less than 2% of residual substrate material in the finished product.

In developing our production processes, Aloha Medicinals looked long and hard at the chemistry of the wild collected fruitbodies, of the mycelia and of the extra-cellular compounds, and all that was known about the bioactivity of each in the human body. We then developed special growing methods including custom made growing chambers, strictly defined growth substrates (no sawdust, straw or compost is used) and specially modified growth parameters such as full year-round climate control for temperature, light cycle, and air quality and composition to maximize the production of the targeted medicinal compounds. By controlling each and every aspect of the growth cycle, Aloha Medicinals is able to produce the best quality, the most potent and the most consistent medicinal mushroom products available anywhere in the world today, while ensuring against all possible contamination of heavy metals, pesticides, herbicides or insect residue as is so common in other mushroom products.

One great advance Aloha Medicinals made to the science of mushroom growing is our patent-pending proprietary methods for growing mushrooms in glass and plastic containers for a long enough period of time to completely bio-convert all of the raw substrate material into fungal tissue and extra-cellular compounds. By the time of harvest we have obtained all of the different health giving aspects that the mushroom present. This long growth period takes at least several months, and for some species it can take up to two years. When a supplier promises they can deliver a finished, custom grown product in 30 to 45 days, you can be certain that the quality will be very low. In nature it takes from months-to-years for a mushroom colony to become established. That is why you find mushrooms growing in the same place year after year. They produce mushrooms every spring just like a tree produces flowers, but the mushroom organism itself exists from year to year in the soil below. To think that we can trick that organism into optimal growth in the lab in just a few weeks is wishful thinking indeed. But this is what many mushroom cultivators claim to do.

For some species, Aloha Medicinals has resorted to extreme culture parameters; for example we grow out our Cordyceps sinensis for a period of time in a warm, oxygen rich environment, after which we drastically lower the temperature to just above freezing, we change the light cycle and we drop the oxygen to no more than 50% of the normal atmospheric content. All of this is done on an organic, vegetarian substrate with no insect or animal substances used. While this may seem extreme compared to how other cultivators grow their medicinal mushroom products, Aloha Medicinals is proud to point out the products we make are the best quality, highest potency medicinal mushroom products in the world. This is proven by the phenomenal growth Aloha Medicinals has experienced over the last 10 years, making us the largest cultivators of exclusively Certified Organic Medicinal Mushrooms today with a monthly production capacity of nearly 200 tons of finished products per month. We currently supply over 700 companies with the raw material used in their formulations, and in 2009 we exported to 56 countries, which won us the U.S. Department of Commerce “Exporter of the Year” Award, the second year in a row we were awarded special recognition for our quality products.

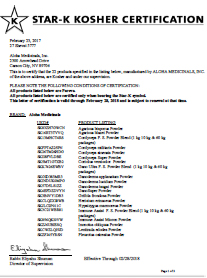

If you want the best medicinal mushroom products available today, Aloha Medicinals is your best choice. 100% Certified Organic by USDA and EU, 100% Certified Kosher by Star K, and 100% Guaranteed. It does not get any better than this. Certified Organic and 100% made in America with all-American ingredients. Why risk the reputation of your products on imported raw materials, when the best quality is available right here in America, using state of the art science and Independently Assayed by FDA certified labs for DNA and Analytical profile. All this is available at a price lower than imported raw materials in most cases. Whether you need Full Spectrum Myco-products, or a concentrated extract, or even research grade materials, we supply it all. Let us bid your next order for medicinal mushroom raw materials. You will be pleasantly surprised!

Purpose of this published study is scientific information and education, it should not be used for diagnosing or treating a health problem or disease. This website is designed for general education and information purposes only and does not substitute for professional medical advice, examination, diagnosis or treatment.

Disclaimer:

This Web site – Information About Herbs, Botanicals and Other Products — is for general health information only. This Web site is not to be used as a substitute for medical advice, diagnosis or treatment of any health condition or problem. Users of this Web site should not rely on information provided on this Web site for their own health problems. Any questions regarding your own health should be addressed to your own physician or other healthcare provider.

This Web site- makes no warranties nor express or implied representations whatsoever regarding the accuracy, completeness, timeliness, comparative or controversial nature, or usefulness of any information contained or referenced on this Web site. This Web site- does not assume any risk whatsoever for your use of this website or the information contained herein. Health-related information changes frequently and therefore information contained on this Web site may be outdated, incomplete or incorrect. Statements made about products have not been evaluated by the Food and Drug Administration. Use of this Web site does not create an expressed or implied physician-patient relationship.

In using this website you agree that neither Worldsalud nor any other party is or will be liable or otherwise responsible for any decision made or any action taken or any action not taken due to your use of any information presented at this website.

Aloha Medicinals unique methods

used to develop highest

quality hybridized strains of Cordyceps Sinensis

Aloha Medicinals unique methods

used to develop highest

quality hybridized strains of Cordyceps Sinensis